The term “value engineering” is often abused in the construction industry. Many contractors represent cost savings to owners by slashing more expensive components of a job in favor of cheaper and often lower quality products. At D&M we believe true value engineering comes from not only a comprehensive analysis of the specific project but the cumulative benefits gained from years of experience, knowledge of codes and staying on the cutting edge of new products and equipment. Combining these elements with a team of personnel who are trained to think “outside the box” and the result is a win-win scenario for the client.

Case Study: LaFarge Gypsum FGD Conversion

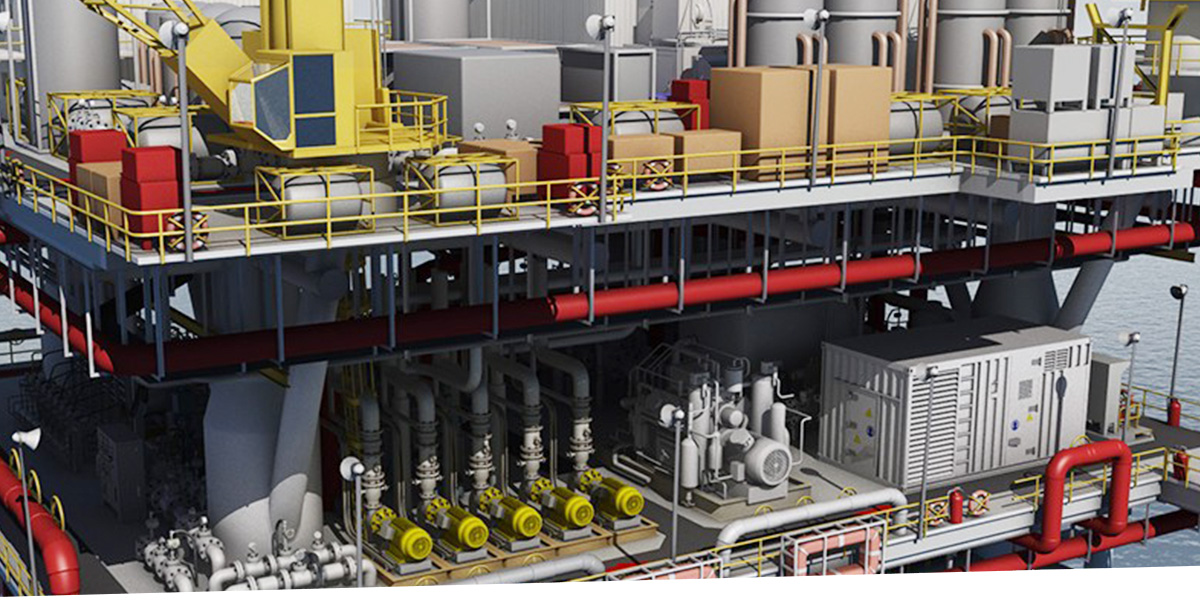

When building product manufacturer LaFarge Gypsum decided to convert their Buchanan, NY sheet rock production facility to a synthetic gypsum substitute, significant modifications and expansions to the plants infrastructure needed to occur. D&M Electrical was awarded contracts for both the site electrical and the off-shore electrical portions of the project. One aspect included the construction of several new off-shore platforms in the Hudson River. The largest of the platforms supported a crane used to unload raw material from barges. The crane and related winches required a 15kV feeder which was specified to run along a catwalk and then into the new electric room. Unfortunately the 5” galvanized rigid conduit which would have been required was too heavy to be supported from the existing catwalk and the bend radii of the sweeps would have encroached upon an exclusion zone which needed to remain clear. D&M’s solution for this problem was an innovative design which utilized a steel messenger cable on the existing conveyer support towers to which a submarine cable was over-lashed. The cable then transitioned into underwater rated fiberglass reinforced epoxy (FRE) conduit mounted to the tower foundations to protect it from mechanical injury before its final position in the mud bed of the Hudson River. The cable then transitioned back into FRE conduit before making its way into the main switchgear. IBEW Local 1249 linemen from D&M Utility worked together with D&M’s IBEW Local 3 inside wiremen to perform the installation. The team was assisted by divers from Atlantic Subsea of Bridgeport, NJ to install the large 48” diameter pulling wheels which are typically used on helicopter driven cable installations. A self-supporting fiber optic inner duct was also installed at the same time as the feeder, cutting installation costs. The end result was a substantial savings to the client as well as a quality installation which was capped off with medium voltage terminations from Raychem, installed by D&M’s splicers under the MVPower Certified Contractor program which qualified the installation for a 20 year factory warranty.

Case Study: Yonkers Animal Shelter

In preparation for the future construction of the new Yonkers Animal Shelter, engineers specified conduit to be installed in the new Ridge Hill Bridge in order to supply power to the new facility. When the project finally was bid several years later, D&M was the low bidder and awarded a prime contract for the electrical construction. Upon coordination with Con Edison, it was determined that the original service layout was no longer viable and a new service entrance point needed to be established. The required accommodation work from Con Edison would cost the City of Yonkers over $150,000.00 payable to the utility and take nearly 9 months to complete. With time being of the essence and the budget of the project being jeopardized, D&M evaluated several options and proposed an alternate service layout to Con Edison which required almost no accommodation work by the utility and resulted in no accommodation charges. D&M performed the work with its own forces, intercepting the previously installed conduits under the bridge and routed the feeder to a new customer owned riser pole. This value engineered solution resulted in a cost savings to the City of Yonkers in excess of $100,000.00. D&M completed the work and had the service energized in less than two months.

Case Study: Southern Westchester Executive Park

When ProCon Construction of Hookset, NH was awarded a project to construct the Hampton Inn at the Southern Westchester Executive Park the first order of business was to relocate (2) 15kV feeders that supplied the entire 12 building, 800,000 square foot office park. The feeders passed directly through the footprint of the new hotel. Due to the original design of the system the typical redundancy that allows for taking one feeder out of service at a time was not an option. Due to tenant constraints the work needed to be performed on a weekend and in 24hrs or less. After a thorough analysis of the situation and a long brainstorming session with the utility, D&M crafted a plan which involved the pre-staging of (7) large tractor trailer mounted 1 and 1.5 megawatt generators at the location of each transformer in the campus (even though there was only need for (6) generators the owner elected to have a spare unit on stand-by). Working closely with Con Edison, the park was de-energized precisely at 9AM on Saturday morning. As (6) D&M crews worked to place the campus on generator power, two other crews began the job of cutting back conduits and splicing the (2) set of feeders at two separate manholes. The work continued round the clock with relief crews staged to assist as needed. The work (inclusive of all testing performed by D&M) was completed well ahead of the 24 hour window (a window that several other contractors stated was not feasible). At 9AM Sunday morning Con Edison crews re-energized the campus. The success of the project led to the following letter of commendation from the property owner, Bob Weinberg of Robert Martin Developers:

To all who participated:

Truly a great story of teamwork and ingenuity both on the business side

and the technical. Practicality, innovation and compromise all were

brought to bear to make it happen. It is a story well worth telling to all

who participated in a small way, many of whom are really unaware of the

complexity of the effort.

If someone could put the saga on paper I would circulate it to the

leaderships which are confident of the capability of their troops, but

totally without a clue about what was entailed in a venture like this.

I am sure that all who lived this event now have a special bond and belief

that nothing is impossible. Although my involvement was truly peripheral,

I appreciate being considered part of the team. My thanks to all!